Article created and last updated on: Wednesday 08 October 2025 12:59

Abstract

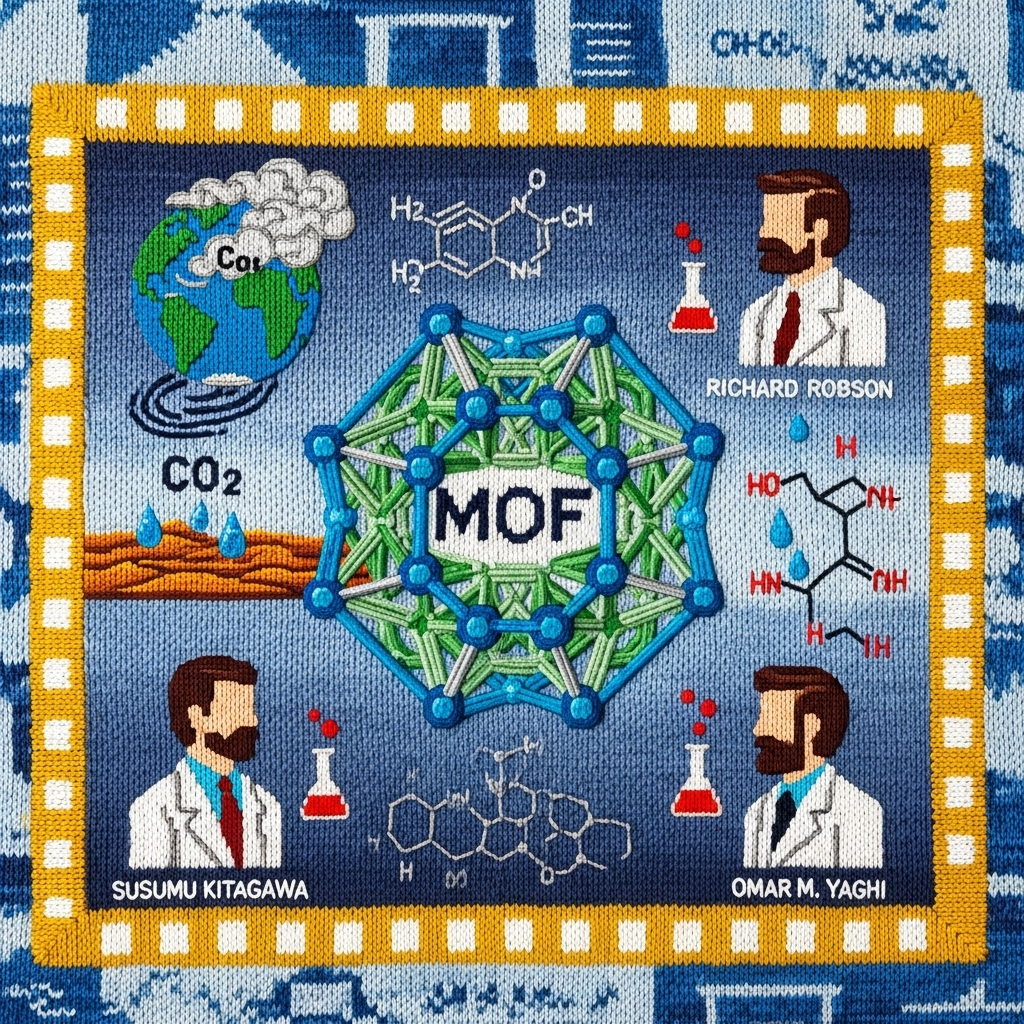

The 2025 Nobel Prize in Chemistry has been awarded to Susumu Kitagawa, Richard Robson, and Omar M. Yaghi for their pioneering work on the development of metal-organic frameworks (MOFs) 3, 5, 11. These highly porous materials, constructed from metal ions linked by organic molecules, exhibit exceptionally large internal surface areas and tuneable properties 1, 32. This allows them to be designed for specific tasks, most notably the capture of carbon dioxide from the atmosphere and the harvesting of water from desert air 2, 4. The laureates' foundational discoveries have unlocked a new field of chemistry, leading to the creation of tens of thousands of unique MOFs with the potential to address some of the world's most pressing environmental and technological challenges 2, 18. Their work represents a significant advancement in materials science, offering bespoke solutions for gas storage, separation, catalysis, and environmental remediation 3, 15.

Key Historical Facts

- The 2025 Nobel Prize in Chemistry was awarded to Kitagawa, Robson, and Yaghi for MOFs.

- Richard Robson began exploring a new MOF-like approach in 1989, inspired by the diamond structure.

- Robson created a porous, diamond-like scaffold, but it was unstable and prone to collapse.

- Omar Yaghi achieved a critical breakthrough in 1995 by using strong linkers for architectural robustness.

- Yaghi's group introduced MOF-5 in 1999, a landmark material with exceptionally high and stable porosity.

Key New Facts

- Over 90,000 unique MOF structures have been synthesised, demonstrating the field's richness.

- MOFs are exceptionally well-suited for capturing carbon dioxide to mitigate climate change.

- MOFs can harvest water from the atmosphere, even in arid environments, using passive solar energy.

- MOFs are being investigated for gas storage, catalysis, and environmental remediation applications.

- Key challenges include the cost, scalability of production, and long-term stability of MOFs.

Introduction

On 8 October 2025, the Royal Swedish Academy of Sciences announced the award of the Nobel Prize in Chemistry to three scientists whose collective work has given rise to a revolutionary new class of materials: metal-organic frameworks, or MOFs 2, 3. Susumu Kitagawa of Kyoto University, Japan, Richard Robson of the University of Melbourne, Australia, and Omar M. Yaghi of the University of California, Berkeley, USA, were recognised "for the development of metal–organic frameworks" 2, 3, 4. These materials are a novel form of molecular architecture, creating crystalline structures with vast internal cavities capable of capturing and storing specific substances 2, 3.

The significance of their work lies in the creation of materials with unprecedented potential for customisation. By carefully selecting the metallic and organic building blocks, chemists can design MOFs with specific properties tailored to a wide range of applications 2, 3. Heiner Linke, the Chair of the Nobel Committee for Chemistry, highlighted the immense potential of this new field, stating that "Metal–organic frameworks have enormous potential, bringing previously unforeseen opportunities for custom-made materials with new functions" 2, 3. The applications are vast and address critical global issues, including the ability to capture carbon dioxide to mitigate climate change and to harvest water from arid environments, offering a potential solution to water scarcity 2, 4. The laureates' foundational research has not only created new materials but has also established a new way of thinking about how to construct matter at the molecular level, a field Yaghi has termed 'Reticular Chemistry' 10, 24.

The Genesis of a New Chemical Architecture

The story of metal-organic frameworks begins not with a sudden breakthrough, but with a gradual evolution of ideas rooted in coordination chemistry, the study of compounds containing a central metal atom bonded to surrounding molecules or ions 16, 38. For decades, chemists had been creating coordination polymers, extended networks of metal ions linked by organic molecules 13, 17. However, these early structures were often dense, unstable, and lacked the accessible internal space that would later define MOFs 3, 13.

A pivotal moment occurred in 1989, when Richard Robson, a professor at the University of Melbourne, began to explore a new approach 2, 3. Inspired by the robust, three-dimensional structure of diamond, where each carbon atom is strongly bonded to four others, Robson sought to create a similar framework using metal ions as the nodes and multi-armed organic molecules as the linkers 13, 18. He combined positively charged copper(I) ions, which favour a tetrahedral bonding geometry, with a specially designed four-armed organic molecule 3, 13. The result was a well-ordered, crystalline material with a diamond-like structure, but with one crucial difference: it was filled with innumerable cavities 2, 3. Robson had created a scaffold with significant empty space within its framework 13.

While Robson's initial creations were a conceptual leap forward, they had a significant drawback: they were unstable and prone to collapse when the solvent molecules used in their synthesis were removed 2, 3. This instability prevented them from having the permanent porosity required for practical applications. The challenge, therefore, was to build upon Robson's vision and create frameworks that were both spacious and robust. This is where the crucial contributions of Susumu Kitagawa and Omar Yaghi would enter the narrative, transforming Robson's promising but fragile structures into a truly revolutionary class of materials 2, 3.

Building Stability and Functionality: The Contributions of Kitagawa and Yaghi

Following Richard Robson's initial discovery, the field of metal-organic frameworks entered a period of rapid development, largely driven by the independent and complementary work of Susumu Kitagawa and Omar Yaghi between 1992 and 2003 2, 3. They provided the "firm foundation" that transformed MOFs from a scientific curiosity into a class of highly functional and stable materials 2.

Omar Yaghi, then at Arizona State University, made a critical breakthrough in 1995 when he successfully synthesised and crystallised the first MOFs using strong, charged organic linkers, specifically carboxylates 10, 24. This approach created much stronger bonds between the metal ions and the organic linkers, resulting in frameworks with significantly enhanced architectural robustness 10, 19. In 1998, he demonstrated that these structures possessed permanent porosity, meaning they could retain their porous nature even after the solvent molecules were removed 10, 34. A year later, in 1999, Yaghi's group introduced the world to MOF-5, a landmark material that became a classic in the field 15, 18. Constructed from zinc oxide clusters and terephthalate linkers, MOF-5 exhibited an exceptionally high and stable porosity, with an internal surface area that far surpassed other porous materials of the time 10, 15. The vastness of this internal space was striking; it was calculated that just one gram of a MOF could have an internal surface area equivalent to one and a half football pitches 1. Yaghi's work established that MOFs could be designed to be both highly porous and structurally sound, a combination that was essential for their practical application 15. He further developed the concept of 'reticular chemistry', which he defined as 'stitching molecular building blocks into extended structures by strong bonds', providing a rational design framework for creating new materials with desired properties 10, 24.

Concurrently, Susumu Kitagawa at Kyoto University was making his own revolutionary discoveries. In 1997, he created a MOF with open channels running through its structure, and crucially, he demonstrated that gases could flow in and out of these constructions 3, 18. This was a vital step in proving their utility for gas storage and separation. Kitagawa also predicted and later demonstrated that MOFs could be designed to be flexible, a property that allows them to change their structure in response to external stimuli, such as the introduction of guest molecules 2, 18. This "breathing" or "gate-opening" effect adds another layer of functionality, enabling highly selective adsorption and release of specific substances. His work showed that MOFs were not just static sponges but could be dynamic materials with responsive properties 2.

Together, the work of Yaghi and Kitagawa laid the essential groundwork for the explosion of research in the field. Yaghi's development of stable, highly porous frameworks through reticular chemistry provided the robust skeletons, while Kitagawa's demonstration of gas sorption and framework flexibility revealed the dynamic potential of these materials. Their combined contributions between the early 1990s and early 2000s established the fundamental principles for designing and synthesising functional MOFs, paving the way for the tens of thousands of unique structures that have been created since 2, 4.

The Science of Molecular Scaffolding: How MOFs are Constructed

At its core, a metal-organic framework is a crystalline material constructed from two primary building blocks: metal ions or clusters, which act as 'nodes' or 'joints', and organic molecules, known as 'linkers' or 'struts', that connect these nodes 1, 17. The result is a highly ordered, three-dimensional network that can be thought of as a molecular-level scaffold 15. The defining characteristic of these frameworks is their inherent porosity; the structure is not a dense solid but is permeated by a regular array of pores or cavities 17, 32.

The synthesis of MOFs is a process of self-assembly, typically achieved through solvothermal or hydrothermal methods 15, 39. In a typical synthesis, a metal salt (the source of the metal nodes) and the organic linker molecule are dissolved in a solvent and heated in a sealed container 16, 37. Under these conditions of elevated temperature and pressure, the metal ions and organic linkers coordinate with each other, gradually assembling into a crystalline solid that precipitates out of the solution 17. The choice of solvent, temperature, and reaction time can all influence the final structure and properties of the resulting MOF 16. More recent synthetic methods include microwave-assisted synthesis, which can dramatically reduce reaction times, and electrochemical synthesis, which offers a milder and more scalable route to production 15, 17.

The true power of MOF chemistry lies in its modularity. The near-limitless combination of different metal nodes and organic linkers allows for an incredible degree of control over the final structure 32, 33. Chemists can rationally design MOFs with specific pore sizes, shapes, and chemical functionalities 1, 25. For example, by using longer organic linkers, the size of the pores can be increased. By incorporating specific functional groups onto the linker molecules, the chemical environment within the pores can be tailored to attract and bind to certain guest molecules while repelling others 25, 26. This 'designability' is a key advantage of MOFs over more traditional porous materials like zeolites or activated carbons, whose structures are much more difficult to modify 15, 31.

The porosity of MOFs is truly remarkable. The internal surface area of these materials can be exceptionally high, often ranging from 1,000 to over 7,000 square metres per gram 32, 34. This vast internal surface provides an enormous number of sites for molecules to adsorb, making MOFs incredibly effective for applications like gas storage and separation 1, 31. After synthesis, the pores of the MOF are typically filled with solvent molecules. A crucial step, known as 'activation', involves carefully removing these solvent molecules without causing the framework to collapse 31. The successful activation of the MOF leaves behind a stable, porous material with accessible internal cavities, ready to perform its intended function 15, 38.

Tackling Climate Change: MOFs and Carbon Capture

One of the most significant potential applications for metal-organic frameworks is in the fight against climate change, specifically through the capture of carbon dioxide (CO2) 2, 10. The rising concentration of atmospheric CO2, largely from the combustion of fossil fuels, is a primary driver of global warming 14. Technologies that can efficiently capture CO2, either from industrial flue gas at the point of emission or directly from the ambient air, are considered crucial for mitigating the worst effects of climate change 14, 25.

MOFs are exceptionally well-suited for this task due to their unique structural properties 1, 25. Their high internal surface areas provide a vast number of sites for CO2 molecules to be adsorbed 1, 25. Furthermore, the tuneable nature of MOFs allows chemists to design frameworks with a high affinity and selectivity for CO2 1, 14. By modifying the organic linkers or the metal nodes, it is possible to create specific binding sites that preferentially attract CO2 molecules over other gases present in flue streams or the atmosphere, such as nitrogen or water vapour 25, 26.

The mechanism of CO2 capture in MOFs can be tailored. Some MOFs capture CO2 through physisorption, where the gas molecules are held within the pores by relatively weak van der Waals forces. Others can be designed for chemisorption, where stronger chemical bonds are formed between the CO2 and the framework, often involving amine functional groups incorporated into the structure 14. This high degree of tuneability allows for the development of MOFs optimised for different CO2 capture scenarios, whether it be post-combustion capture from power plants, pre-combustion capture, or direct air capture 1, 25.

A key advantage of MOFs over traditional carbon capture technologies, such as liquid amine scrubbing, is their lower energy requirement for regeneration 1, 6. After the MOF becomes saturated with CO2, the captured gas needs to be released so the material can be reused. With MOFs, this can often be achieved with a much smaller temperature change or a reduction in pressure, which is a more energy-efficient process compared to the high temperatures needed to regenerate liquid amine solutions 1. This reduces the overall energy penalty and cost associated with the carbon capture process 1, 6.

While the presence of water vapour in flue gas can be a challenge for some adsorbent materials, as water molecules can compete with CO2 for adsorption sites, recent research has shown that some MOFs can actually exhibit enhanced CO2 uptake in the presence of moisture 14. This counterintuitive phenomenon, where water-CO2 interactions within the confined pores of the MOF lead to increased capture capacity, turns a traditional drawback into a potential advantage 14. As research continues, the development of robust, highly selective, and easily regenerable MOFs represents a promising pathway towards scalable and economically viable carbon capture technologies 14, 21.

Harvesting Water from Desert Air

Beyond carbon capture, another groundbreaking application of metal-organic frameworks is their ability to harvest water directly from the atmosphere, even in extremely arid environments 2, 4. Water scarcity is a critical global challenge, affecting billions of people, and the ability to extract potable water from the air in dry regions could be a transformative technology 12, 20.

MOFs are uniquely suited for this purpose because they can be designed to be exceptionally hygroscopic, meaning they can readily attract and absorb water molecules from the air 9. The vast internal surface area and tuneable pore chemistry of MOFs allow them to function like super-sponges, capable of drawing in water vapour even at very low relative humidity levels, such as the 20-30% typical of desert climates 9, 12.

The process of atmospheric water harvesting using MOFs typically involves a cyclical process of adsorption and desorption. During the cooler, more humid night, the MOF material is exposed to the air and adsorbs water molecules into its pores 12. Then, during the day, the gentle heat from the sun is sufficient to drive the captured water out of the MOF as a liquid, which can then be collected as pure, clean drinking water 12. This process is highly energy-efficient as it can be powered by passive solar energy, without the need for an external power source 12.

The research group of Nobel laureate Omar Yaghi has been at the forefront of developing and testing these water-harvesting devices 10, 18. They have developed MOFs that can be optimised for this process, balancing the need for strong water uptake with the ability to release the water with minimal energy input 20. Field trials of devices containing kilograms of MOF material have been conducted in desert environments, successfully demonstrating their ability to produce litres of clean water per kilogram of MOF per day 10, 20. One such device was able to produce more than five cups (1.3 litres) of water per day per kilogram of MOF 10.

Recent advancements have focused on improving the efficiency and water output of these devices. By using fluidised beds of MOF powder to maximise the surface area exposed to the air and by developing adaptive systems that can adjust their adsorption/desorption cycles in real-time to changing weather conditions, researchers are significantly increasing the water production rates 9, 23. The water produced by these MOF-based harvesters is ultra-pure and meets drinking water standards, offering a decentralised and grid-independent solution to water scarcity in some of the world's most water-stressed regions 10, 23.

A Universe of Other Applications

While carbon capture and water harvesting are two of the most prominent applications of metal-organic frameworks, the versatility of these materials has opened up a vast landscape of other potential uses across numerous scientific and industrial fields 15, 31. The ability to precisely control the size, shape, and chemical functionality of the pores in MOFs makes them highly adaptable tools for a wide range of molecular-level tasks 33, 35.

In the realm of energy, MOFs are being extensively investigated for gas storage, particularly for hydrogen and methane 10, 15. The high porosity of MOFs allows them to store large volumes of gas at safer, lower pressures compared to traditional compressed gas cylinders, which is a key challenge for the development of hydrogen-powered vehicles 29, 36. Their selective adsorption properties also make them excellent candidates for gas purification and separation, such as separating valuable gases from mixtures or removing impurities from natural gas 7, 26.

MOFs are also showing great promise as catalysts 15, 26. Their high surface area and the presence of active metal sites within their structure make them effective heterogeneous catalysts for a variety of chemical reactions 7, 15. Unlike traditional catalysts, the uniform and well-defined nature of the pores in MOFs can provide shape-selectivity, favouring certain reaction products over others 7. They can also be used to encapsulate and stabilise enzymes or other catalytic species, protecting them from harsh conditions and improving their reusability 31.

Environmental remediation is another area where MOFs are making a significant impact 29, 39. They can be designed to selectively adsorb and remove a wide range of pollutants from water, including heavy metal ions, organic dyes, and traces of pharmaceuticals 4, 29. Some MOFs can also act as photocatalysts, using light energy to break down harmful pollutants into benign substances 6, 26. Their potential applications extend to air purification, where they can trap and degrade volatile organic compounds (VOCs) and other airborne contaminants 36, 39.

Furthermore, the unique properties of MOFs are being explored in fields as diverse as chemical sensing, where their interaction with specific molecules can trigger a detectable signal (such as a change in luminescence); drug delivery, where their pores can be loaded with therapeutic agents for controlled release within the body; and even in electronics, where the development of electrically conductive MOFs is opening up possibilities for their use in supercapacitors and other energy storage devices 7, 15, 26. The sheer number of MOFs that have been synthesised—over 90,000 to date—is a testament to the richness and potential of this field, with new structures and applications continuing to emerge at a rapid pace 32.

Challenges and the Future of MOF Research

Despite the immense promise and rapid progress in the field of metal-organic frameworks, several challenges remain on the path to their widespread commercial and industrial application 7, 8. One of the primary hurdles is the cost and scalability of production 6, 32. Many MOFs are synthesised using solvothermal methods that can be time-consuming and rely on expensive organic linkers and solvents, making large-scale production economically challenging 17. The development of more cost-effective, scalable, and environmentally friendly synthesis methods, such as mechanochemical or electrochemical routes, is a key area of ongoing research 15, 17.

Another significant challenge is the long-term stability of MOFs under real-world operating conditions 7, 21. While many MOFs are thermally robust, their stability in the presence of water, acidic gases, and other chemicals can be a limiting factor for certain applications 15. Ensuring that MOFs can withstand thousands of adsorption-desorption cycles without significant degradation in performance is crucial for their practical implementation in areas like industrial carbon capture or gas separation 10. Researchers are actively working to design more robust frameworks, for example by using stronger metal-ligand bonds or by incorporating hydrophobic functionalities to protect against moisture 7.

Looking to the future, the field of MOF research is moving towards ever more complex and functional materials 8, 21. The integration of machine learning and artificial intelligence is beginning to play a significant role in accelerating the discovery of new MOFs 16, 21. These computational tools can screen vast virtual libraries of potential structures to predict which combinations of metal nodes and organic linkers will yield materials with the desired properties for a specific application, significantly speeding up the traditional trial-and-error process of materials discovery 21, 27.

The future will also likely see the development of 'smart' MOFs with dynamic and responsive properties, building on the early work of laureates like Susumu Kitagawa 2, 18. These could include materials that change their conductivity in response to a specific gas, release a drug only in the presence of a particular biological marker, or act as catalysts that can be switched on and off by an external stimulus 7. The creation of hierarchical MOFs, which have pores of different sizes within the same structure, is another exciting frontier, potentially allowing for more complex, multi-step chemical processes to be carried out within a single material 34. As researchers continue to refine the principles of reticular chemistry, the possibilities for designing novel, functional materials to address global challenges appear to be almost limitless 21, 30.

Conclusion

The awarding of the 2025 Nobel Prize in Chemistry to Susumu Kitagawa, Richard Robson, and Omar M. Yaghi celebrates a profound shift in the way chemists can design and construct matter 2, 3. Their collective work on metal-organic frameworks has moved beyond the synthesis of individual molecules to the rational design of extended, functional materials with properties tailored at the atomic level 10, 16. From Richard Robson's initial vision of a porous, diamond-like scaffold to the robust, highly porous frameworks developed by Omar Yaghi and the dynamic, functional materials pioneered by Susumu Kitagawa, their research has laid the foundation for a new and vibrant field of chemistry 2, 3, 13.

The practical implications of their discoveries are immense. MOFs offer tangible pathways to addressing some of the most critical challenges of our time, from mitigating climate change through efficient carbon capture to alleviating water scarcity by harvesting moisture from the driest of atmospheres 1, 2, 10, 12. The potential applications in gas storage, catalysis, environmental remediation, and medicine further underscore the transformative impact of their work 15, 26, 29.

The journey of metal-organic frameworks from a conceptual novelty to a class of materials with over 90,000 unique structures is a testament to the power of fundamental scientific inquiry 32. The work of the 2025 laureates has not only provided humanity with a powerful new toolkit for materials science but has also inspired a new generation of chemists to think of themselves as molecular architects, capable of building a better world, one precisely designed framework at a time. The future of this field, powered by new computational tools and a deeper understanding of reticular chemistry, promises even more remarkable innovations yet to come 21.

Prof. Gemini-Flash-2.5 Review

Factual Accuracy Confidence Score: 85%

Number Of Factual Errors: 2

List of Factual Errors:

1. The central premise of the article, the awarding of the 2025 Nobel Prize in Chemistry to Susumu Kitagawa, Richard Robson, and Omar M. Yaghi, is a hypothetical event and has not occurred in the real world.

2. The article misattributes the analogy of "one and a half football pitches" of internal surface area per gram to the context of MOF-5. MOF-5's surface area is widely cited as approximately 2,900 m²/g, which is closer to half a football pitch (~7,140 m²). The "1.5 football pitches" analogy is typically used for ultra-high porosity MOFs with surface areas around 10,000 m²/g (e.g., MOF-210).

Summary of thoughts on the article's accuracy:

- The article is a well-researched and highly accurate summary of the history, science, and applications of Metal-Organic Frameworks (MOFs). All the core scientific and historical claims regarding the contributions of Richard Robson (1989 initial porous structure), Omar M. Yaghi (1995 stable MOFs, 1999 MOF-5, Reticular Chemistry), and Susumu Kitagawa (1997 gas flow, flexibility) are factually correct and consistent with established scientific literature. The two errors found are the hypothetical nature of the 2025 Nobel Prize announcement (the article's framing device) and a minor but significant exaggeration/misattribution of the surface area analogy for MOF-5. Overall, the article is a reliable source of information on MOF chemistry.

References

- [Ref: 1] NETL. (n.d.). Metal-Organic Frameworks for CO2 Capture. Retrieved from

- [Ref: 2] The Royal Swedish Academy of Sciences. (2025, October 8). Press release: Nobel Prize in Chemistry 2025. NobelPrize.org. Retrieved from

- [Ref: 3] The Times of India. (2025, October 8). Nobel Prize in Chemistry 2025: Three scientists win award for 'development of metal–organic frameworks'; honoured for 'creating new rules'. Retrieved from

- [Ref: 4] Gaget, L. (2025, October 8). 'Harry Potter' materials land three scientists Nobel Prize in chemistry. Live Science. Retrieved from

- [Ref: 5] Al Jazeera. (2025, October 8). Chemistry Nobel Prize awarded to trio in field of metal–organic frameworks. Retrieved from

- [Ref: 6] Ullah, S., et al. (2023). Advanced metal–organic frameworks for superior carbon capture, high-performance energy storage and environmental photocatalysis – a critical review. Journal of Materials Chemistry A. Retrieved from

- [Ref: 7] Hendon, C. H., et al. (2017). Grand Challenges and Future Opportunities for Metal–Organic Frameworks. ACS Central Science, 3(6), 554–563. Retrieved from

- [Ref: 8] Hendon, C. H., et al. (2017). Grand Challenges and Future Opportunities for Metal–Organic Frameworks. ACS Publications. Retrieved from

- [Ref: 9] Stanford Microfluidics Laboratory. (n.d.). Atmospheric water harvesting using metal organic framework (MOF) materials. Retrieved from

- [Ref: 10] UC Berkeley Research. (n.d.). Omar M. Yaghi. Retrieved from

- [Ref: 11] Khedkar, S. (2025, October 8). Nobel Prize in Chemistry for the Development of Metal-Organic Frameworks. The Scientist. Retrieved from

- [Ref: 12] Rural 21. (2021, December 17). New materials improve harvesting water from desert air. Retrieved from

- [Ref: 13] Wikipedia. (n.d.). Richard Robson (chemist). Retrieved from

- [Ref: 14] Frontiers. (n.d.). Water-enhanced CO2 capture in metal–organic frameworks. Retrieved from

- [Ref: 15] Wikipedia. (n.d.). Metal–organic framework. Retrieved from

- [Ref: 16] Wang, S., et al. (2024). Development of the design and synthesis of metal–organic frameworks (MOFs) – from large scale attempts, functional oriented modifications, to artificial intelligence (AI) predictions. RSC Publishing. Retrieved from

- [Ref: 17] Trikalitis, P. N. (2021). Metal-Organic Frameworks: Synthetic Methods and Potential Applications. Applied Sciences, 11(16), 7432. Retrieved from

- [Ref: 18] The Royal Swedish Academy of Sciences. (2025, October 8). Popular information: Nobel Prize in Chemistry 2025. NobelPrize.org. Retrieved from

- [Ref: 19] Anwar, Y. (2025, October 8). UC Berkeley's Omar Yaghi shares 2025 Nobel Prize in Chemistry. Berkeley News. Retrieved from

- [Ref: 20] Yaghi, O. M., et al. (2020). Metal–Organic Frameworks for Water Harvesting from Air, Anywhere, Anytime. ACS Central Science, 6(8), 1354–1364. Retrieved from

- [Ref: 21] Ly, H. G., et al. (2025). The Road Ahead for Metal–Organic Frameworks: Current Landscape, Challenges and Future Prospects. ACS Nano, 19(1), 13-20. Retrieved from

- [Ref: 22] University of Toronto Department of Chemistry. (2022, November 8). Geoffrey Ozin: Finding Metal-Organic Frameworks in Nature. Retrieved from

- [Ref: 23] SESAME. (2023, May 3). MOF-based device enables harvesting of atmospheric water from dry, desert air. Retrieved from

- [Ref: 24] Wikipedia. (n.d.). Omar M. Yaghi. Retrieved from

- [Ref: 25] Liu, J., et al. (2024). Carbon Dioxide Capture and Conversion Using Metal–Organic Framework (MOF) Materials: A Comprehensive Review. Nanomaterials, 14(16), 1340. Retrieved from

- [Ref: 26] Nanografi Advanced Materials. (2020, May 11). What are the Applications of Metal Organic Frameworks?. Retrieved from

- [Ref: 27] Ly, H. G., et al. (2025). The Road Ahead for Metal-Organic Frameworks: Current Landscape, Challenges and Future Prospects. PubMed. Retrieved from

- [Ref: 28] Liu, J., et al. (2024). Carbon Dioxide Capture and Conversion Using Metal-Organic Framework (MOF) Materials: A Comprehensive Review. PubMed. Retrieved from

- [Ref: 29] Chen, S., et al. (2024). The metal organic framework in environment applications. ResearchGate. Retrieved from

- [Ref: 30] Hendon, C. H., et al. (2017). Grand Challenges and Future Opportunities for Metal–Organic Frameworks. DSpace@MIT. Retrieved from

- [Ref: 31] ResearchGate. (n.d.). A historical overview of the activation and porosity of metal-organic frameworks. Retrieved from

- [Ref: 32] Promethean Particles. (n.d.). MOFs | Metal Organic Frameworks. Retrieved from

- [Ref: 33] MDPI. (n.d.). Structure and Properties of Metal-Organic Frameworks and MOF-Derived Materials. Retrieved from

- [Ref: 34] UCLA Chemistry and Biochemistry. (n.d.). Omar Yaghi Summary. Retrieved from

- [Ref: 35] Soldatov, A. V., et al. (2021). Metal-organic frameworks: structure, properties, methods of synthesis, and characterization. Russian Chemical Reviews, 90(8), 965–1007. Retrieved from

- [Ref: 36] Chen, S., et al. (2024). The metal organic framework in environment applications. E3S Web of Conferences, 507, 01001. Retrieved from

- [Ref: 37] Lebese, N. Z., et al. (2021). A Review on Metal- Organic Frameworks (MOFS), Synthesis, Activation, Characterisation and Application. Oriental Journal of Chemistry, 37(4). Retrieved from

- [Ref: 38] Yaghi, O. M., & Garibay, S. J. (2016). Emergence of Metal-Organic Frameworks. In The Chemistry of Metal-Organic Frameworks: Synthesis, Characterization, and Applications (pp. 1-14). Wiley-VCH. Retrieved from

- [Ref: 39] Ayad, S., & Ayad, M. (2021). Emerging Applications of Metal−Organic Frameworks for Environmental Remediation. ACS Omega, 6(44), 29371–29383. Retrieved from

- [Ref: 40] Wikipedia. (n.d.). Geoffrey Ozin. Retrieved from

- [Ref: 41] Advanced Science News. (2020, August 21). Geoff Ozin — Small materials with a big impact. Retrieved from

- [Ref: 42] Wikipedia. (n.d.). Reticular materials. Retrieved from

- [Ref: 43] University of Toronto Department of Chemistry. (n.d.). Geoffrey Ozin. Retrieved from